As roscas dos tubos variam consoante as normas nacionais e internacionais e o campo de aplicação. Este artigo descreve as diferenças e compatibilidades entre as roscas BSPP (ou gás), BSPT e NPT.

Tipos de roscas de tubos

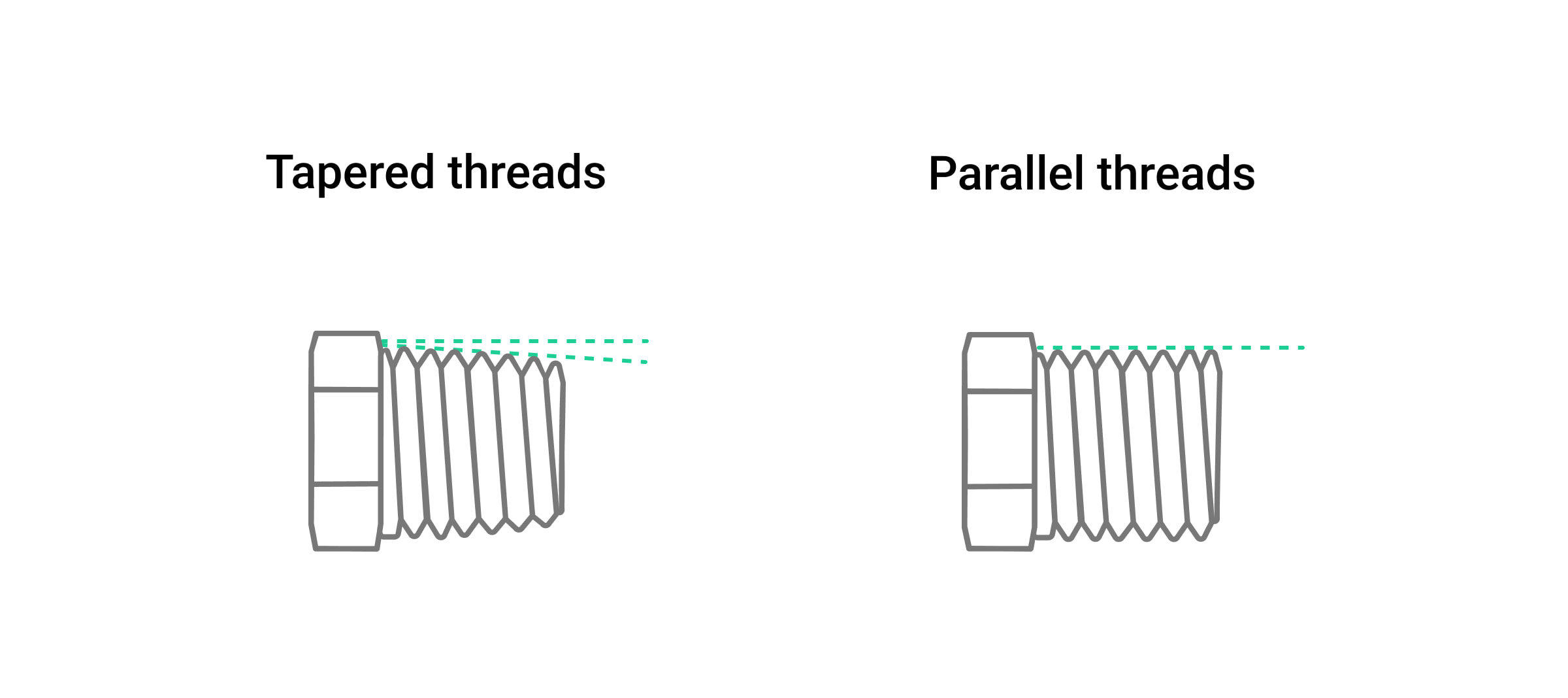

Existem dois tipos básicos de rosca de tubo:

- Paralela (também chamada reta) — o diâmetro da rosca do tubo é constante.

- Cónica — o diâmetro da rosca do tubo não é constante. Aumenta ou diminui à medida que o comprimento da rosca avança.

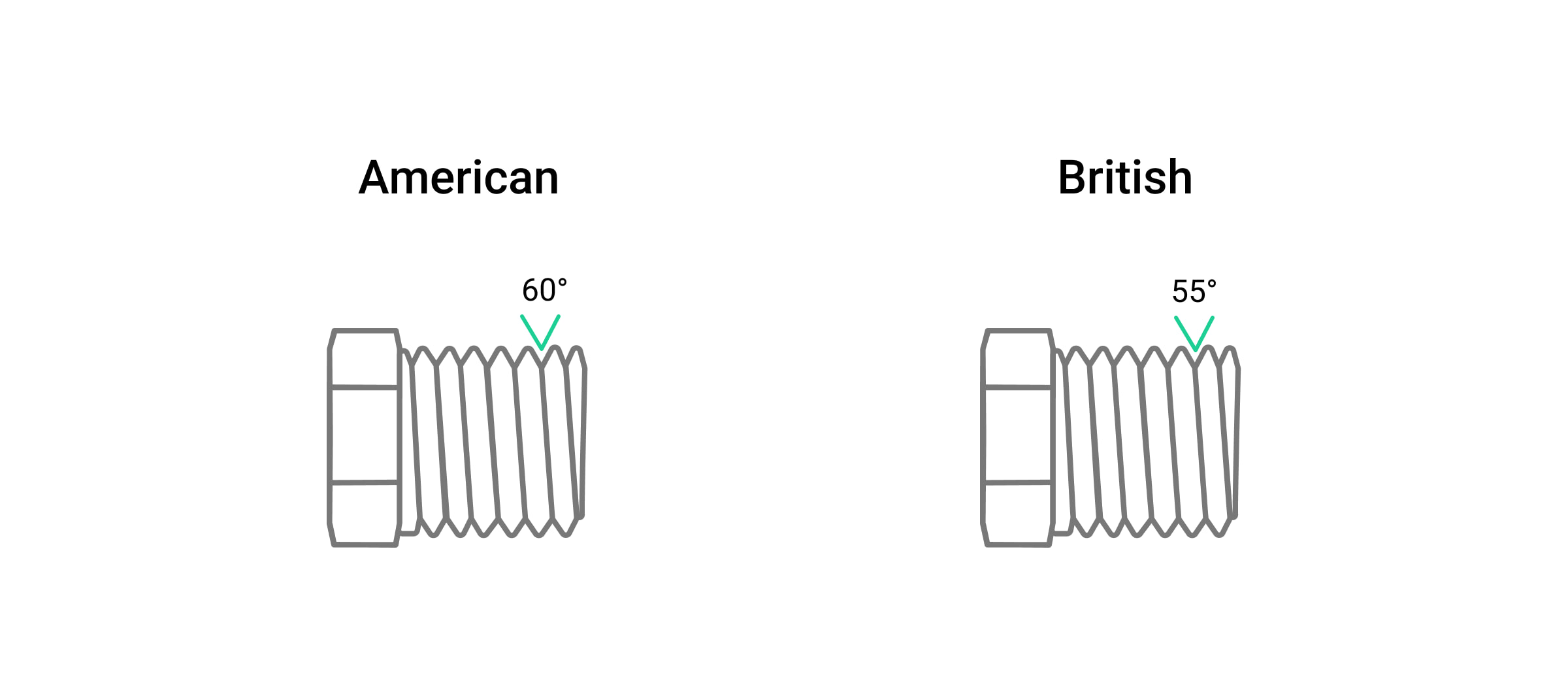

Existem dois padrões mais comuns de roscas para tubos:

- British Standard Pipe Thread (BSP) baseia-se numa rosca angular de 55 graus. Esta norma foi adotada em todo o mundo (exceto na América do Norte).

- American National Standard Pipe Thread baseia-se numa rosca angular de 60 graus. Esta norma é a mais utilizada nos Estados Unidos e no Canadá.

Além disso, cada padrão de rosca de tubo apresenta um número específico de roscas por polegada e diferentes formas de picos e vales de rosca.

Rosca BSPP

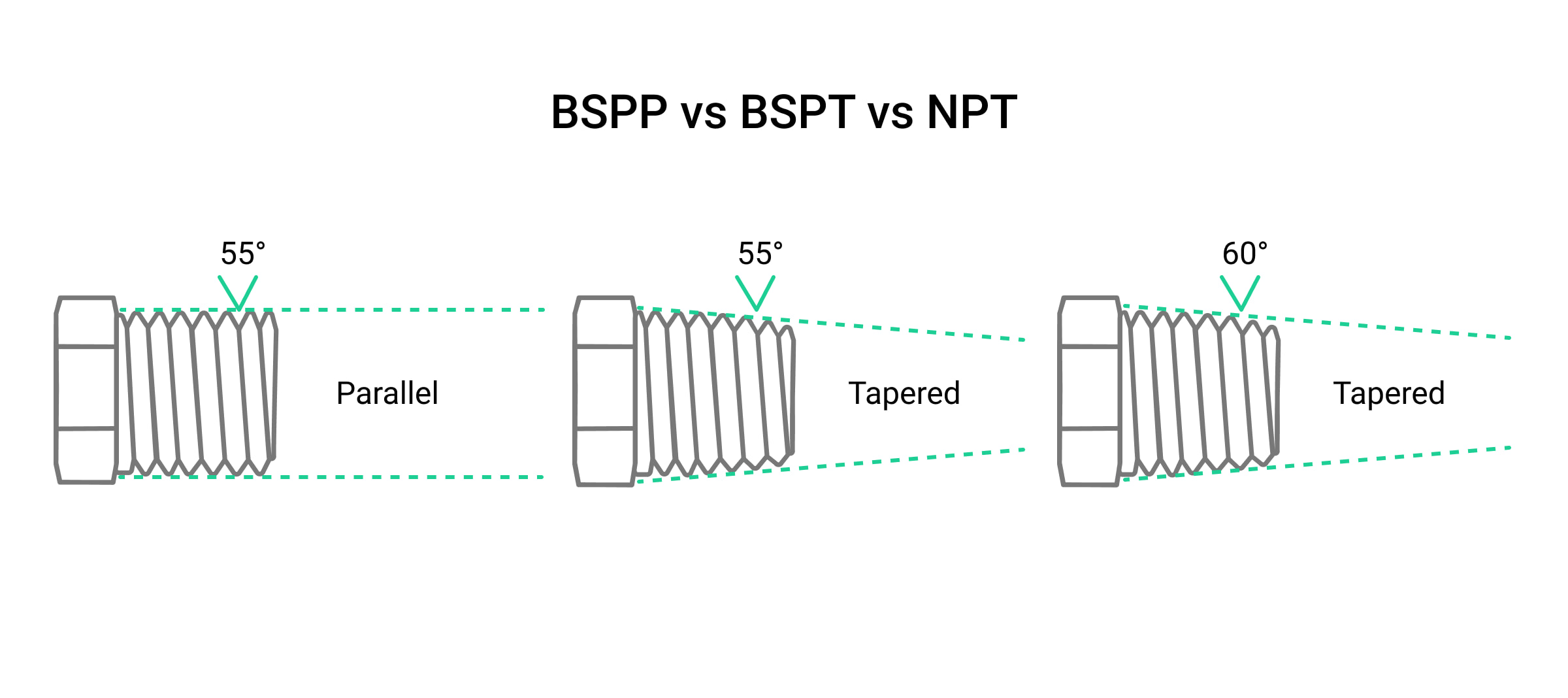

A rosca BSPP (ou de gás) é uma rosca paralela da norma BSP (o P no final significa “Paralela“, como regra, para a diferenciar da rosca cónica). Tem um diâmetro constante, um ângulo de 55 graus, e picos e vales arredondados.

As roscas macho e fêmea BSPP são sempre paralelas, ou seja, montadas com a mesma forma cilíndrica. Para estes tipos de roscas, recomenda-se a utilização de um vedante.

Rosca BSPT

A rosca BSPT é uma rosca cónica da norma BSP (o T no final significa Taper (Cónico), como regra, para a diferenciar da rosca paralela). O diâmetro desta rosca de tubo varia ao longo do comprimento da rosca. A rosca BSPT tem o mesmo ângulo de 55 graus com picos e vales arredondados.

As roscas macho e fêmea BSPT comprimem-se e unem-se entre si. Como resultado, estas ligações são mais rígidas, à prova de fugas e não requerem a utilização de vedante.

Rosca NPT

A rosca NPT (National Pipe Taper) é uma rosca cónica da norma American National Standard Pipe Thread. O diâmetro desta rosca de tubo varia ao longo do comprimento da rosca. A rosca NPT tem um ângulo de 60 graus com picos e vales achatados.

As ligações de rosca NPT também não requerem a utilização de vedante, uma vez que as roscas cónicas macho e fêmea se comprimem e unem, proporcionando ligações à prova de fugas.

A figura seguinte mostra a diferença de forma entre as roscas BSPP, BSPT e NPT:

As roscas BSPP e BSPT são compatíveis?

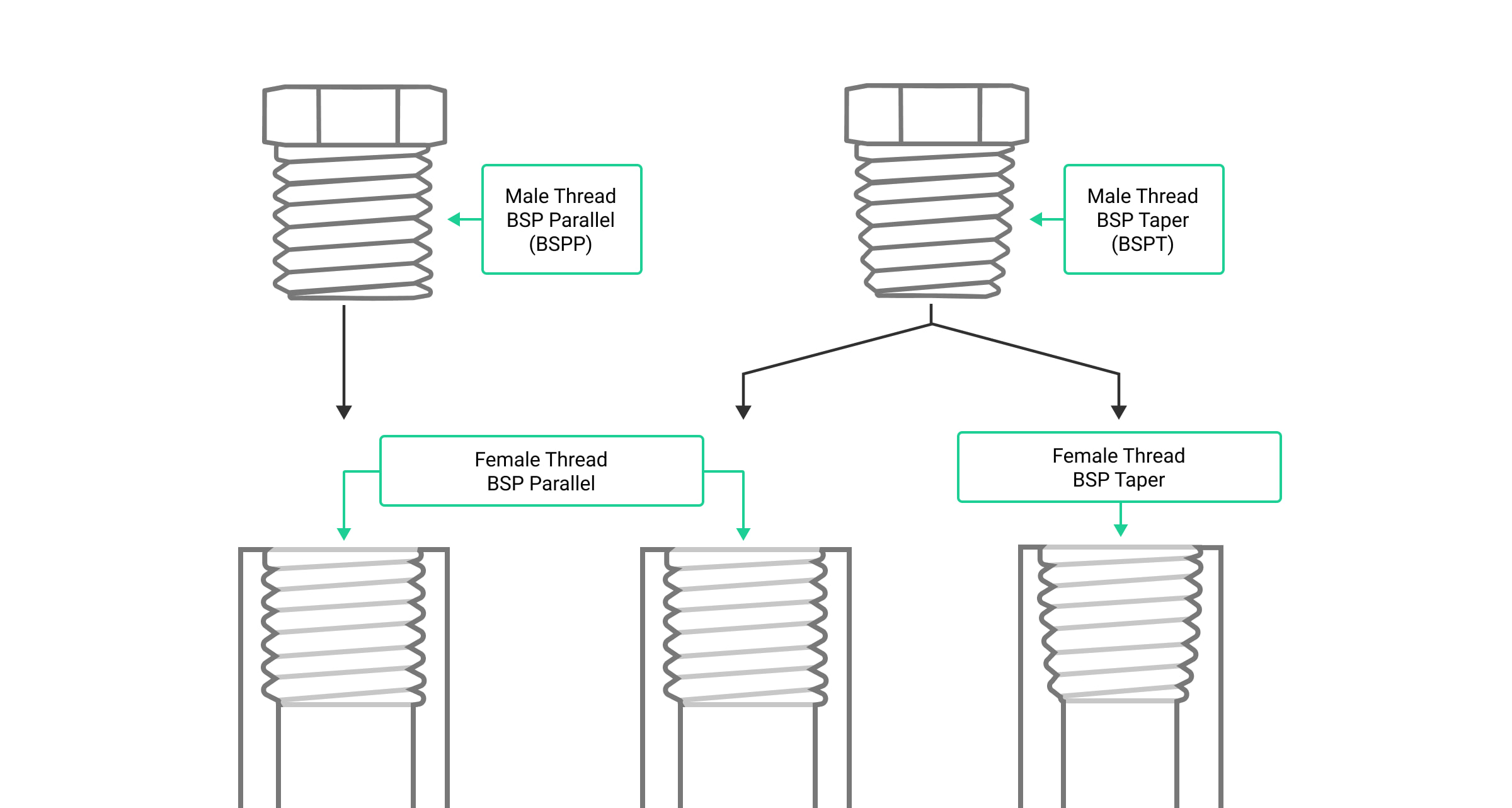

A regra de ouro é simples: um macho cónico pode encaixar numa fêmea cónica ou paralela.

Por conseguinte, uma rosca macho BSPT (cónica) pode encaixar tanto numa rosca fêmea BSPT (cónica) como numa rosca fêmea BSPP (paralela). No entanto, uma rosca macho BSPP (paralela) encaixa apenas numa rosca fêmea paralela (BSPP), uma vez que é impossível encaixar numa fêmea cónica.

Tudo isto está ilustrado na figura seguinte:

Note que a ligação de um macho BSPT a uma fêmea BSPP requer um vedante adicional para garantir uma ligação à prova de fugas.

As roscas BSP e NPT são incompatíveis, uma vez que têm números diferentes de roscas por polegada e ângulos de rosca. A tentativa de unir um macho NPT a uma fêmea BSPP ou BSPT fará com que a junta fique presa em poucas voltas. Como resultado, ocorrerá uma fuga em espiral devido à diferença na forma da rosca.

Compatibilidade com roscas BSP e NPT

| BSPP fêmea | BSPT fêmea | NPT fêmea | |

| BSPP macho | + | – | – |

| BSPT macho | + | + | – |

| NPT macho | – | – | + |

Que ligações requerem um adaptador de rosca?

É necessário um adaptador de rosca para ligar os tubos com roscas incompatíveis. Utilizar o adaptador com os tipos de rosca adequados para garantir ligações rígidas e estanques.

Para mais informações sobre combinações de roscas de tubos compatíveis e incompatíveis, consulte a tabela acima.

Que ligações roscadas requerem a aplicação de vedante?

É necessário um vedante para ligações de rosca paralela ou reta (por exemplo, BSPP).

Além disso, o vedante é necessário quando se liga uma rosca macho cónica a uma rosca fêmea paralela (por exemplo, um macho BSPT a uma fêmea BSPP).

As ligações de rosca cónica (por exemplo, BSPT, NPT) não requerem a utilização de vedante, uma vez que as roscas cónicas macho e fêmea se comprimem e unem, proporcionando ligações estanques.